You know very well that Two-Platen injection molding machines are best.

Now learn why OURS are head-and-shoulders above the rest because of ultra-advanced technologies from Mitsubishi!

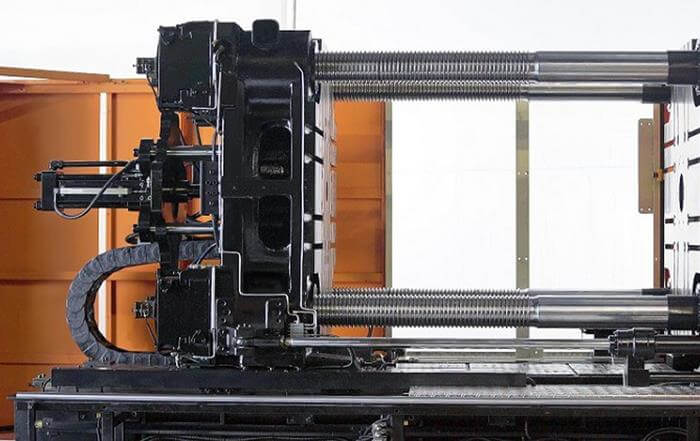

Largest Stroke & Daylight

Advanced two-platen design provides the largest stroke and daylight into the smallest footprint possible!

Japanese Design

High-end Japanese-based designs deliver high precision, high stability, high speed, and ultimate mould protection without any of the traditional compromises.

Standards Compliant

Feature Complete

European-standard, IEC 61131-compliant, advanced computer controllers from Beckhoff® and B&R®, employing high-speed digital buses such as EtherCAT™ and PowerLink®, give you the reliability, flexibility, programmability and expandability you require.

One-Stop Flexible Programming

We own the IP (intellectual property) of the controllers on all our machines. You don’t have to go anywhere else for customization or adaptations — we can do it all for you in-house.

Productivity

Clamping speed of up to 750mm/s makes this one of the fastest two-platen designs around. Very short cycle time and high productivity is all but assured.

Patented Mechanics

Patented inter-locking mechanism ensures quiet, silky-smooth movements with high precision and repeatability, even when running at top speed.

Energy Saving

SVP/3 servo-drive literally sips electricity! It is unbelievably energy-efficient and friendly to the environment! Saves up to 80% electricity and cooling water consumption.

Servo-Drive

SVP/3 (third-generation advanced servo-control) technology has swift responses and superior dynamics.

Mould Protection

Achieve the ultimate in mould protection through high-precision and highly-sensitive hydraulics.

Advanced hydraulics control technology enables hair-grained motion control with ultra-high precision for demanding applications such as Compressive Moulding. Repeatability within ±0.2% is regularly achieved.

Mix ‘n Match

Unique modular design from the ground up enables you to choose from a wide variety of possible combinations — 14 clamping units and 29 injection units. One of these must be EXACTLY what you need; why settle for anything less?

Truly GIGANTIC

The largest clamping unit goes up to a whopping 6,500 tons! The largest injection unit packs a shot-weight of 110kg! You can make truly gigantic stuff with these machines!

Y-Injectors

4Unique Y-shaped dual-injectors technology allows for further flexibility in mix ‘n match — and a whole new world of possibilities!

Precision-Hydraulics

A team of Japanese and European technical experts took the time-tested hydraulic circuits in our machinery and relentlessly fine-tuned/optimized them to perfection, aided by the latest fluid dynamics simulation software.

The result? Hydraulics so smooth, reliable and snappy that must be seen to believe.

Tuned and Optimized

Unnecessary pressure drops are all but eliminated through multiple rounds of optimizations by Japanese experts.

No Overshoots

Normal hydraulic circuits are subject to overshoots and fluctuations, which get worse with faster response times. Precision Hydraulics™ eliminates these instabilities even at high speeds.

No Fluctuations

You know that keeping stable pressure during filling and packing helps ensure great, consistent product quality.

Done!

You also know that it is easier said than done, unless you are using Precision Hydraulics™

Light as Air, Prevalent as Air

“Air-bag” system for your injection moulding machine! “AIR Buffer” stands for Algorithmic Interlocked Response — a superior mould-protection technology with such supreme sensitivity that it consistently detects and protects against even a single sheet of A4 paper (0.1mm thick) during top-speed clamp closing — a truly amazing feat of engineering made possible by the interlocking dynamics of very high hydraulics precision, optimized mechanical design and advanced patented control algorithms!

Large Machines Too!

Try for yourself: put a piece of A4 paper into a 3,600-ton two-platen machine… we won’t spoil the fun, but prepare to be shocked.

AIR Buffer™ is available for all machine models featuring Precision Hydraulics™ — yes, that includes the advanced two-platen large-tonnage machines!

Try It!

Put a sheet of normal A4 paper between the mould of a machine (in this example a JM168-MK6) running at top speed (100%) and pressure (100%) settings, then watch the mould protection feature at work!

The piece of A4 paper is not even punctured through! Now THAT’S real mould protection!

Eliminate Edge Cases

There are just a few of those edge cases that keep giving you headaches — high pressure stabilization, precise low-speed control, switch-over at high speeds etc. The Enhanced Stability Control Pack adds additional control mechanisms to eliminate them for you. Makes regular operations even smoother too!

Case File

A product (disposable cups) that was originally running on a high-end Ferromatik machine at over 3.5 seconds.

Can a standard Chen Hsong machine (in this case the SPEED168) produce the same products with the same quality (preferably better) and at the same speed (preferably faster)?

Result

- Injection Speed: 300mm/s

- Shot Weight: 12g each

- Cavities: 2

- Cycle Time: 2.9 sec.

- Repeatability: ±0.05%

- Yield: >99.8%

Annual Down-Time as Low as 0.5%!

Unscheduled down-time can be a major headache, but is often a necessary evil.

How do you get Real reliability without breaking the bank?

Pursuit of Excellence

The Japanese, as a people, is relentless in pursuing the holy grail of Zero Defects and making their products last a VERY long time.

A team of Japanese technical experts used their know-how to create the technology that we now simply call: Non-Stop™.

Two-Platen

Available first on the 2nd-Generation Two-Platen machines. Other machine models will follow.

Foundations of Reliability

The philosophy of Not-Making-Things-Worse is the cornerstone of achieving great reliability — that means reducing unnecessary wear-and-tear whenever possible.

Smooth as Silk

Hydraulics systems relentlessly fine-tuned and optimized by European and Japanese experts to minimize pressure drops and eliminate spikes and over-shoots turn all mechanical motions to silky smoothness.

Designed Robustness

Patented mechanical designs have ample margins of safety built-in, allowing superior performance while maintaining the machine at top shape for as long as possible.

Reliable Components

A system is only as reliable as its weakest link — or the worse quality component. True Reliability is not obtained via skimming on costs for cheap materials and parts.

Lightning-Speed

Fast dynamic controls technology is key towards smooth, shocks-free mechanical motions. Interrupt-driven, Hard-Real-Time controls with closed-loop feedback is a must.

Adaptive Intelligence

The prevalence of signal noises, hydraulic spikes, mechanical shocks, temperature fluctuations and normal wear-and-tear means that rigid dynamical systems degrade over time in an not-totally-predictable manner.

In order to maintain stable performance and high precision, misaligned components must be promptly compensated for and brought back into alignment automatically and dynamically through adaptive algorithms.